Benchmark Case

Very famous cases in the industry

Three Gorges Xinghua Bay Offshore Wind Farm Project

The Xinghua Bay Offshore Wind Farm is located on the southeast side of Jiangyin Peninsula and the northwest side of Niutouwei in Fuqing City, Fujian Province, specifically in the northern part of Xinghua Bay. The first phase of the offshore wind farm project involves the installation of 14 wind turbines with a total installed capacity of 77.4 MW. The annual power generation is approximately 216.739 million kWh, which can save the nation about 68,270 tons of standard coal per year. Additionally, it reduces sulfur dioxide emissions by about 101.87 tons/year, carbon dioxide emissions by about 139,800 tons/year, nitrogen oxide emissions by about 93.2 tons/year, and dust emissions by about 19.51 tons/year.

To meet the demands of this project, our company has temporarily established a dedicated production line. We utilize high-quality raw materials from renowned domestic steel mills and operate around the clock to ensure seamless production, surface treatment, quality inspection, packaging, and delivery. We have assigned on-site supervisors and dedicated transportation to guarantee timely delivery within 48 hours after packaging. Thanks to our superior product quality and exceptional delivery service, we have received high praise and recognition from our clients. As a result, we have been invited to continue our collaboration for the second phase of the offshore wind farm project. The Xinghua Bay Offshore Wind Farm project has selected large-capacity wind turbines from eight leading domestic and international manufacturers, with individual unit capacities ranging between 5-6.7 MW. Our company supplies a portion of the stainless steel fasteners required for the assembly of these wind turbines. As this project is the world's first internationalized large-capacity offshore wind test site featuring the most diverse range of international and domestic brands, it holds significant importance for China's exploration of offshore clean energy and the more efficient utilization of wind power. Consequently, our clients have set high standards for the quality, performance, and delivery timelines of our products. The second phase of the Xinghua Bay Offshore Wind Farm has an installed capacity of approximately 280 MW, with an annual power generation of about 818.738 million kWh. This phase will save the nation about 255,000 tons of standard coal per year, reduce sulfur dioxide emissions by about 420.75 tons/year, carbon dioxide emissions by about 663,100 tons/year, nitrogen oxide emissions by about 1,989 tons/year, and dust emissions by about 24.48 tons/year. The first phase of the Xinghua Bay Offshore Wind Farm project will serve as a model for the large-scale development of offshore wind power in Fujian, helping to select suitable turbine models and identify appropriate enterprises for the Fujian Three Gorges Offshore Wind Power International Industrial Park. Meanwhile, the second phase will act as a batch testing site for the wind turbines produced in the industrial park.

Huangshuidongdiao

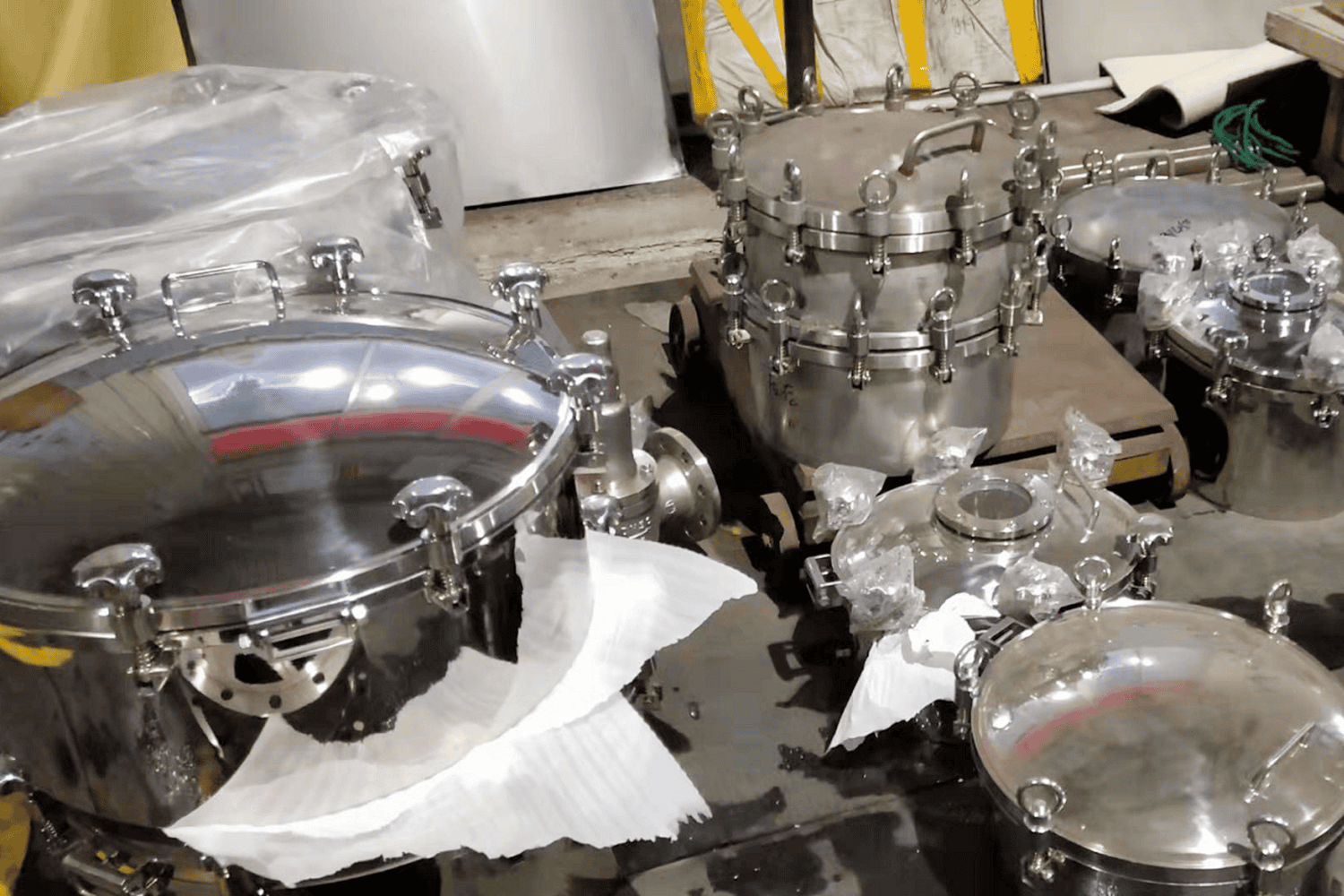

The Huangshui East Water Diversion Project is designed with a flow rate of 15 cubic meters per second and an annual water supply capacity of approximately 315 million cubic meters. The total budget for the project is as high as 6.503 billion yuan. The project is divided into three phases, with a total steel pipe usage of over 400,000 tons. The valves required for pipeline installation and connection are supplied entirely by our company's client, while our company provides the necessary fasteners for the valve assembly, including stainless steel hex bolts, nuts, lifting rings, and other related products.

The Huangshui East Water Diversion Project has demanded significant human, material, and financial resources. With its massive scale and tight construction schedule, it has posed a challenging and demanding task for our client, and this pressure has extended to our company as well. However, in terms of both the quality of the fasteners and the delivery timeline, our company has excelled, indirectly supplying hundreds of thousands of sets of products in various specifications. Together with our client, we have made a substantial contribution to ensuring water supply security and promoting economic development in four cities in Shandong Province.

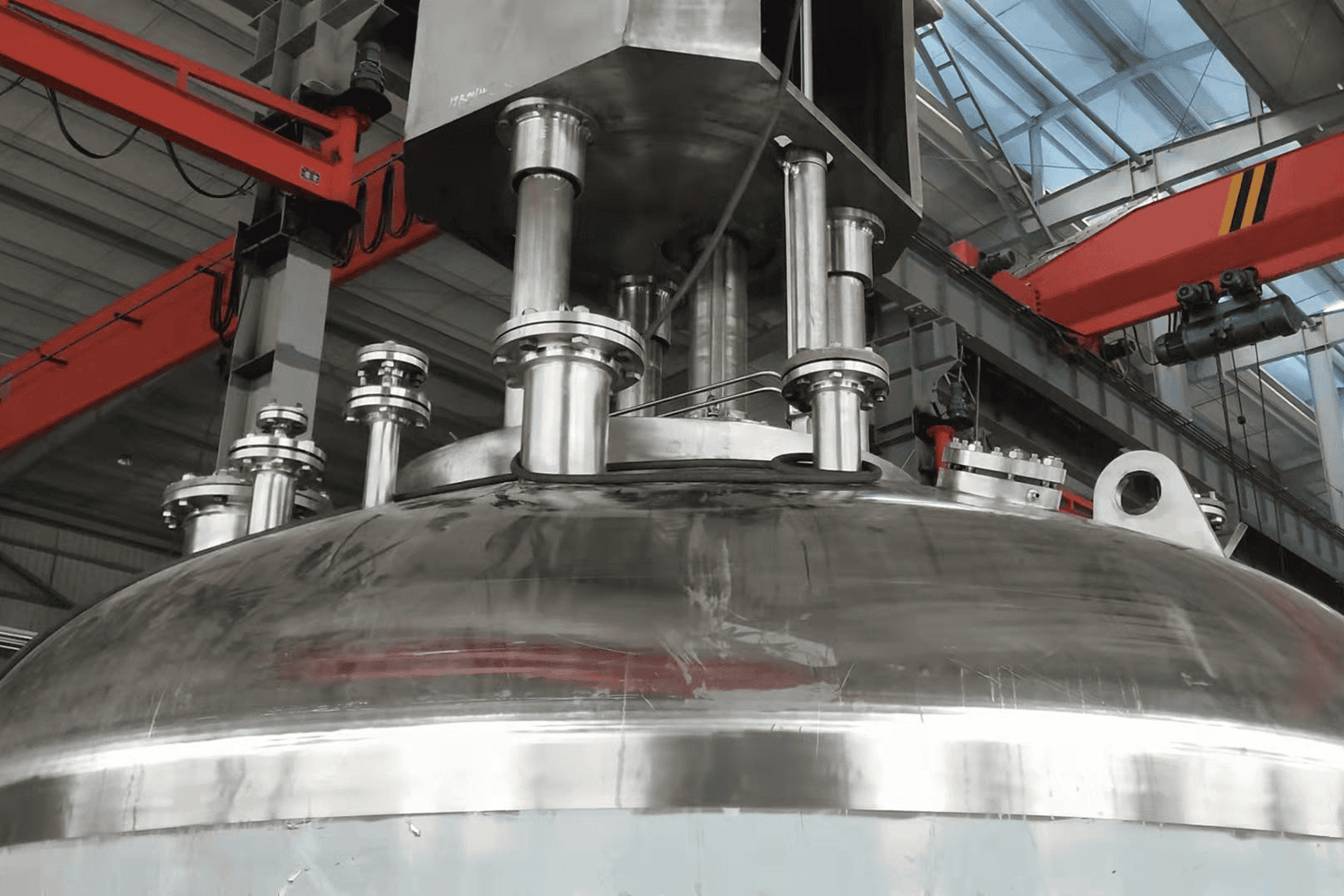

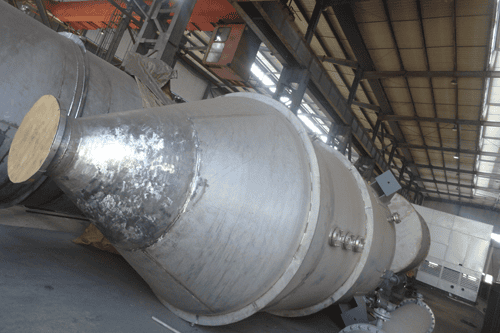

Dongying United Petrochemical Project

The Dongying United Petrochemical 2.6 million tons/year heavy oil hydrocracking and supporting project is located in the Dongying Port Economic Development Zone, a national-level petrochemical industrial zone and one of the four major port industrial zones designated under the "Yellow and Blue" national strategies. The project primarily involves the construction of a new 2.6 million tons/year hydrocracking unit, a 250,000 tons/year isomerization unit, a 120,000 tons/year PSA hydrogen concentration unit, a 200,000 tons/year sulfuric acid unit, and supporting facilities.

As a demonstration project for the transformation and upgrading of the petrochemical industry cluster, the project incorporates world-class patented technologies in its production processes, with process automation reaching leading domestic standards. It serves as a critical raw material project for Dongying United Petrochemical's downstream aromatic industry and represents a key step in accelerating industrial transformation, upgrading, and the shift from traditional refining to a dual focus on refining and chemical production. The project involves substantial investment and numerous facilities, with valves being one of the most widely used pieces of equipment in the production units. The petrochemical industry operates under high-temperature, high-pressure, flammable, explosive, corrosive, and toxic conditions, with continuous production cycles typically lasting 2–3 years before major maintenance can be performed. If a single piece of equipment fails, the entire unit must be shut down. If a unit cannot resume production quickly, the entire plant will cease operations, resulting in incalculable daily economic losses.

In the event of a fire or explosion, significant damage to human life and property could occur. Therefore, the petrochemical industry imposes stringent requirements on equipment quality. For valve manufacturers, it is essential to prioritize product quality while ensuring performance. From the valve materials down to every screw, no compromises are allowed—no substandard materials, no inferior substitutes, and no cutting corners. A long-term cooperative client of Wanqian has supplied valve products for the Dongying United Petrochemical 2.6 million tons/year heavy oil hydrocracking and supporting project. The high-quality products were delivered on time and met all specifications, earning unanimous praise from end-users. Wanqian, with its high-quality fastener products and professional service, has also gained recognition and acclaim from its clients.

Fuping Railway

The Fuping Railway commenced construction on October 31, 2013, entered the joint commissioning and testing phase on September 30, 2020, and officially opened for operation on December 26, 2020, when the G5322 high-speed train departed from Pingtan Station to Fuzhou Station. This marked the official launch of the Fuping Railway, reducing the travel time between Fuzhou and Pingtan to just 35 minutes.

The Fuping Railway starts from Fuzhou Station, extends southeast through Changle District of Fuzhou City, and crosses the Haitan Strait via a bridge to reach Pingtan Island. With a total length of 88.433 kilometers, it is a Class I double-track railway for both passenger and freight transport in China. The Fuping Railway connects with the Hefei-Fuzhou High-Speed Railway, the Hangzhou-Shenzhen High-Speed Railway, and the Changfu Railway within the Fuzhou hub, further enhancing the regional railway network in northeastern Fujian. It serves as a critical transportation guarantee for supporting the open development of the Pingtan Comprehensive Experimental Zone and accelerating the construction of Fuzhou's Binhai New Town. The completion and opening of the Fuping Railway have ended the history of Pingtan Island being inaccessible by rail. Pingtan, Changle, and the old urban area of Fuzhou will now form a "half-hour living circle." This is of great significance for strengthening Fuzhou's role as a central hub, driving the overall open development of northeastern Fujian, and supporting the Belt and Road Initiative.

Our company supplied fastener products for the anchoring connection methods required by the Fuping Railway project. Depending on the application environment and strength requirements, we tailored the details of our products accordingly. Thanks to our meticulous and rigorous approach, we ultimately earned high praise and recognition from both our clients and the project stakeholders.

2022 Hangzhou Asian Games Baseball (Softball) Stadium Project

The 2022 Hangzhou Asian Games are just around the corner, and Shaoxing is set to host events for basketball, volleyball, baseball, softball, and climbing, as well as football training, making it the city outside Hangzhou with the most Asian Games events. Among these, the Baseball and Softball Sports Cultural Center, one of the sub-venues, covers a total construction area of approximately 160,000 square meters with a total investment of about 1.8 billion yuan. Construction officially began on June 28, 2020.

On June 30, 2021, the physical training hall of the Baseball and Softball Sports Cultural Center project was successfully topped out, marking the completion of the concrete structures for all six major facilities: the training center, physical training hall, main baseball field, secondary baseball field, main softball field, and secondary softball field. The Baseball and Softball Sports Cultural Center project faced numerous construction challenges and technical difficulties, such as the complex structure of the main baseball stadium and its numerous curved elements. However, through the concerted efforts of all parties involved, the project was completed ahead of schedule without compromising quality. It is reported that the basement was topped out just six months after construction began, and the main baseball stadium was sealed 40 days ahead of schedule. The completion of the structural work signifies that the project has entered a new phase. Subsequent work will focus on the installation of mechanical and electrical equipment, curtain walls, interior finishing, exterior decoration, and sports facilities. The goal is to complete all aspects except for the interior finishing of the training center by the end of October, ensuring the venue is in optimal condition and fully functional for the upcoming games.

Meanwhile, the first phase of the municipal road construction project for the Baseball Future Community began in June and is expected to be completed and operational by June 2022, in preparation for the Asian Games. Once completed, the Baseball and Softball Sports Cultural Center will become the largest facility of its kind in China, meeting international competition standards. It will provide comprehensive support for the Asian Games and may also serve as a training base for national teams or a provincial team training center in the future.

Thailand 7000DWT Product Oil Tanker and Chemical Tanker

Among our company's customers, a considerable number are engaged in the shipbuilding industry. Since they work in the marine environment for a long time, the fasteners required by these customers are generally made of stainless steel, such as equal-length studs, eye nuts, butterfly nuts, live bolts, pins, etc. Customers have high requirements for the quality of this series of fasteners, especially for their corrosion resistance and rust resistance.

The screws supplied by our company are all made of high-quality 304 and 316 stainless steel, and are fully automatically inspected by optical inspection machines and quality inspected by authoritative third-party inspection agencies to ensure that customers get the best products. According to customer feedback, the projects in which our company's fastener products are finally applied include: Singapore 75m marine work maintenance ship, Malaysia 7000DWT finished oil tanker, Thailand 7000DWT finished oil tanker and chemical tanker, and ocean squid fishing boat. These ships and other ships manufactured by our customers have an average length of more than 70 meters, an average width of more than 20 meters, an average load of about 10,000 tons, and an average endurance of about 9,000 nautical miles. They can basically operate in global waters except the North and South Poles, involving rescue and salvage, saturation diving, deep-water marine engineering hoisting operations, and pipe laying operations. Ships equipped with advanced technology can even perform deep-water emergency rescue and salvage operations far away from the support of the mainland base and in harsh sea conditions.

Based on our company's excellent product quality, fast delivery and good service, our customers have established a long-term and good cooperative relationship with our company. The fastener products supplied by our company have also been involved in more projects, achieving a win-win brand for Wanqian and our customers.

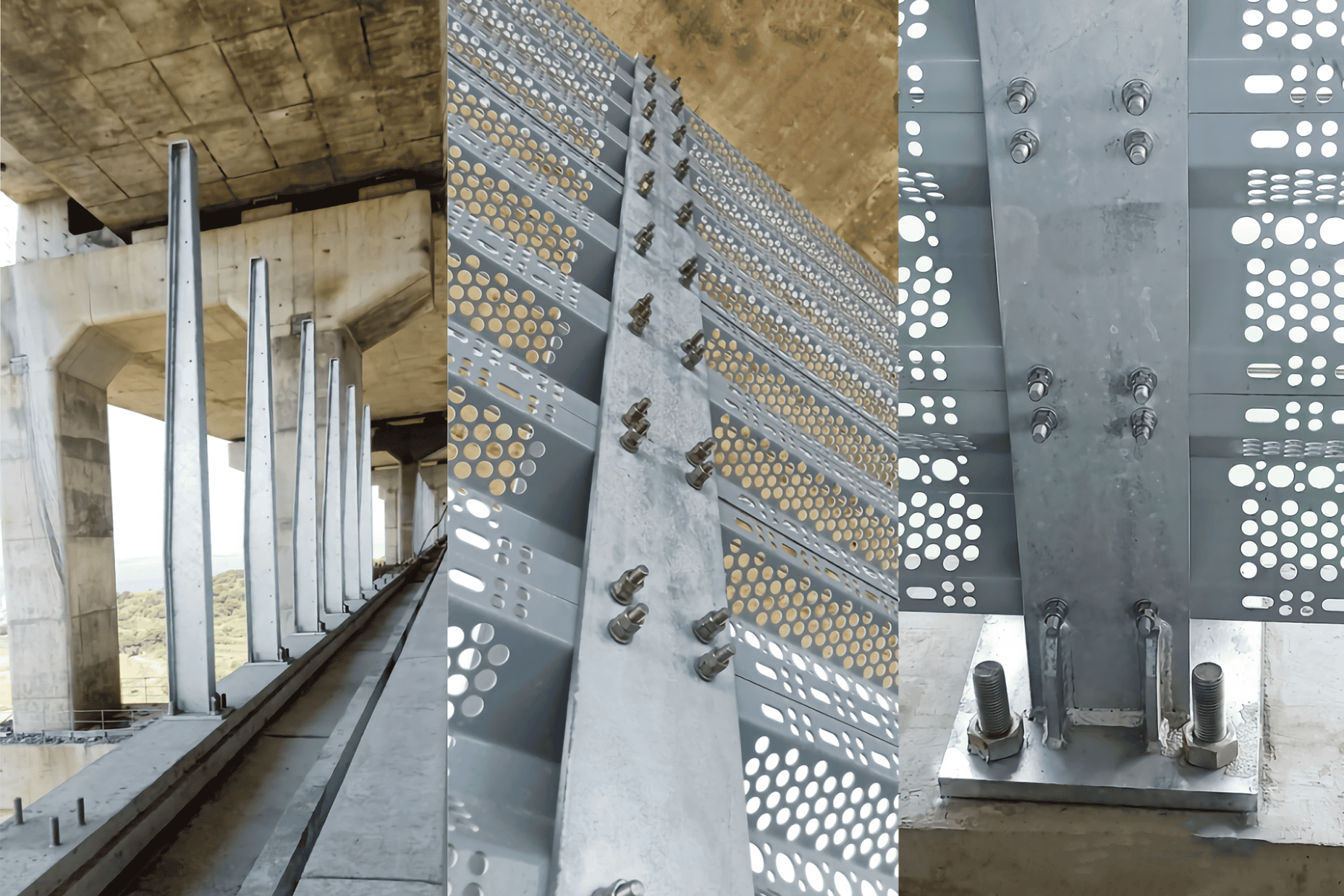

Pingtan Strait Highway-Rail Bridge

On December 26, 2020, the Pingtan Strait Highway-Rail Bridge, my country's first cross-sea highway-rail bridge and the world's longest cross-strait highway-rail bridge, was fully opened to traffic. This means that Pingtan Island has ended its history of not having a railway, which is of great significance for improving the railway transportation network in northeastern Fujian, giving play to the role of Fuzhou as a central hub, and promoting the overall opening and development of northeastern Fujian. The site of the bridge is characterized by strong winds, high waves, deep water and rapid currents. The maximum tidal range can reach 7 meters, and the water flow rate is fast, which has a great impact on underwater structures. At the same time, strong winds and typhoons are frequent throughout the year, which are obstacles both on and off the water. During the construction of the bridge, a series of new structures, new materials, new processes, and new equipment were used to successfully solve the problem of bridge construction under harsh and complex marine environmental conditions.

During the entire construction process, the main construction party has extremely strict requirements for any link. As a supplier of fasteners for the bridge frame of the highway-railway dual-use cross-sea bridge, our company is well aware of its heavy responsibilities. For this reason, in view of the environment in which the bridge is located, our company has taken a number of preventive and improvement measures from both production and quality inspection to ensure that the product meets the requirements, including product quality, hardness, corrosion resistance, fastening strength, and durability. It is commendable that our company finally achieved the goal with high quality, and therefore won the trust of customers and is willing to form a long-term and good cooperative relationship with Wanqian.

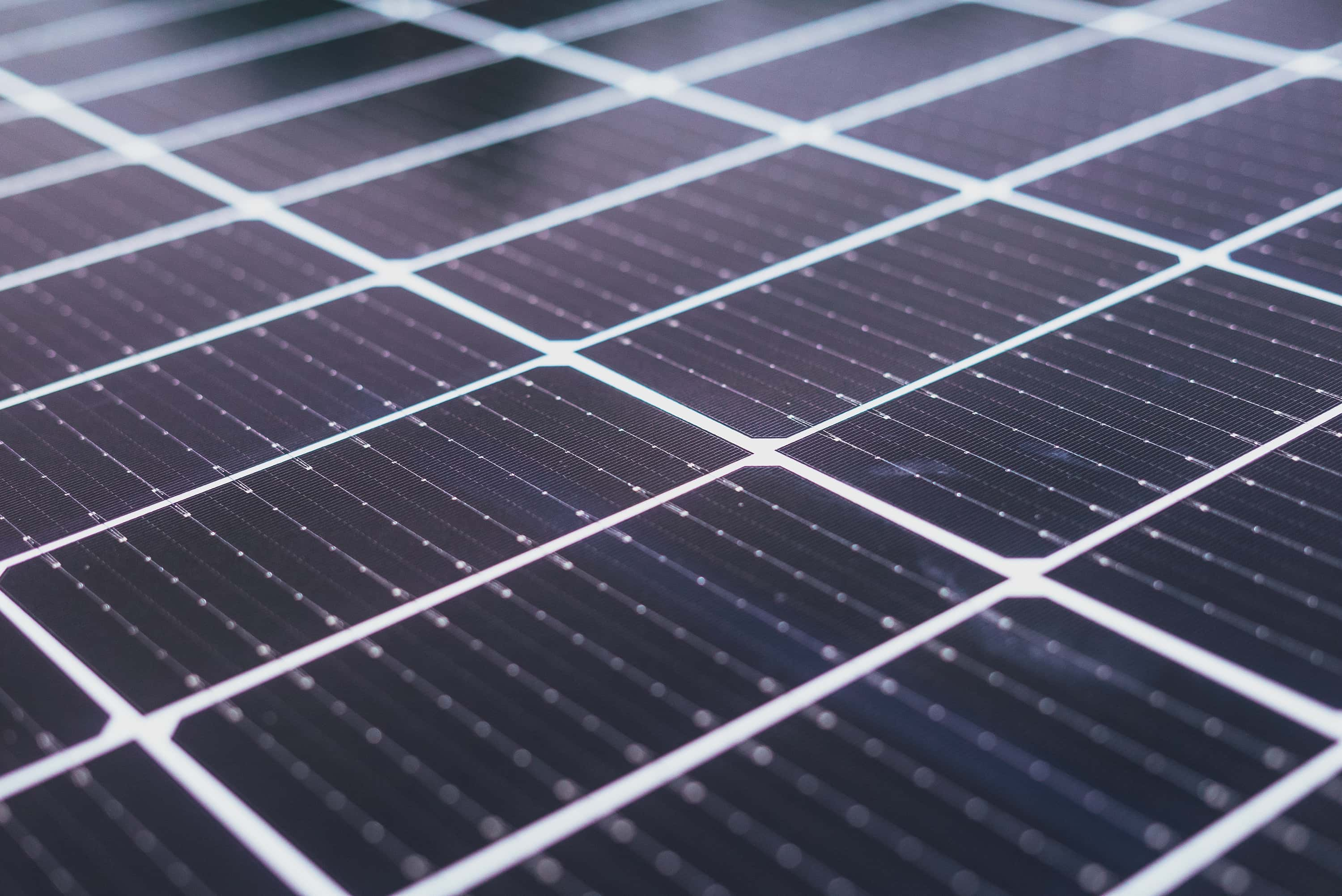

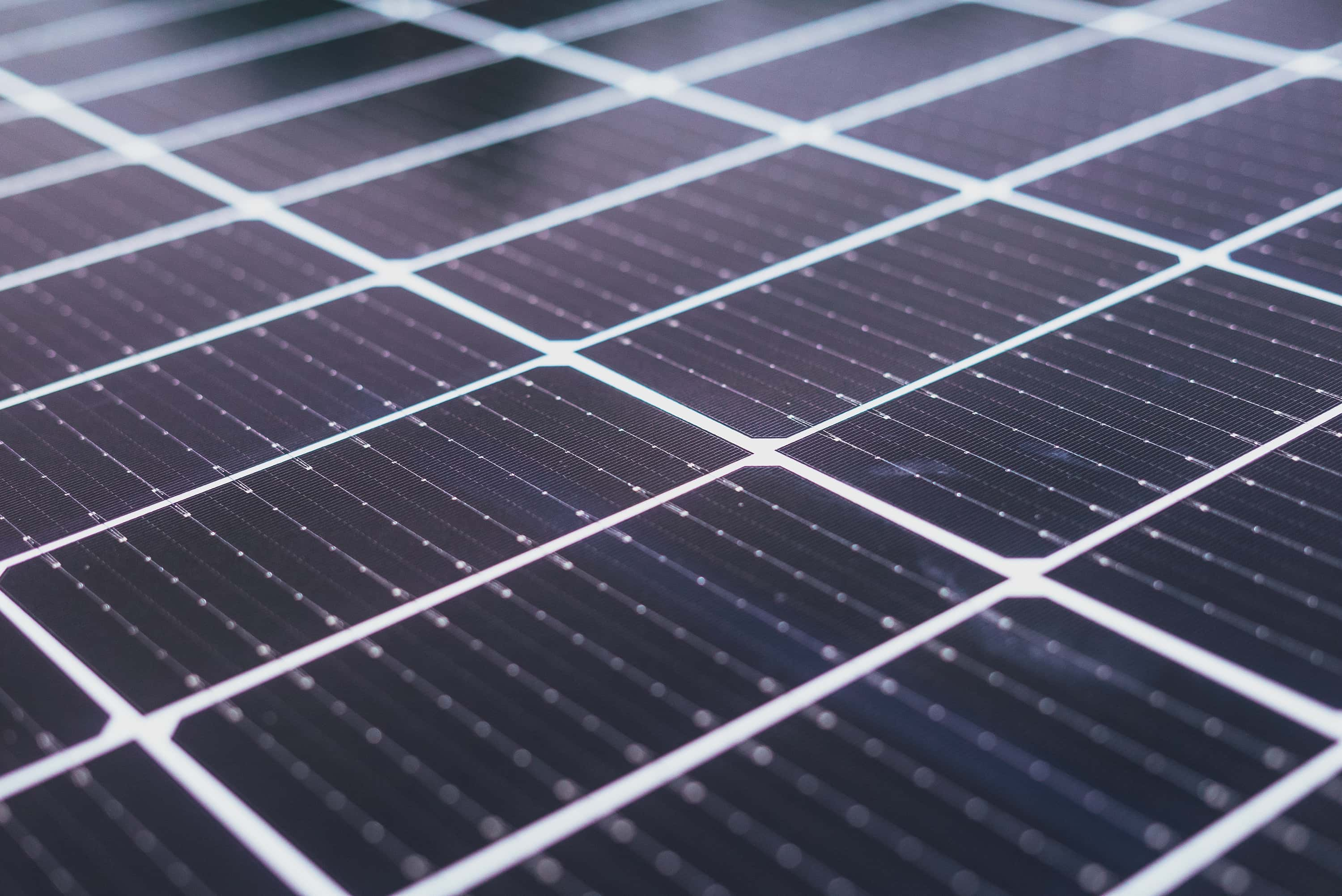

Shanxi Ruicheng 150MW photovoltaic project

Among my company's customer base, quite a few are engaged in the photovoltaic industry. Photovoltaic, to put it simply, is solar power generation. Solar energy has been developed for decades, but it was not until last year that the clean energy of photovoltaics was suddenly taken seriously because of the two words "carbon peak" and "carbon neutrality". In the past, due to technical limitations, the cost of photovoltaic power generation was too high, but with the iteration of technology and the rapid upgrading of the industry, the cost of photovoltaic power generation has dropped by more than 90% in the past ten years. Coupled with policy promotion, the demand for photovoltaic equipment has surged, which can be seen from the greatly increased number of customers in the photovoltaic industry. Therefore, my company followed the footsteps of customers and participated in many photovoltaic projects.

On December 26, 2019, the second phase of the Mo Nan 150MW photovoltaic project of the Ruicheng Leading Technology Base in Shanxi Province was successfully connected to the grid. After completion, the project will be connected with the first phase of Ruicheng County Photovoltaic, making Ruicheng the largest county-level photovoltaic leading technology base in the country. This project can make full use of local geological conditions and light resources to produce clean energy and help local poverty alleviation. Our company provides fastener products required for photovoltaic bracket installation and construction for this project, mainly stainless steel standard parts, including T-bolts, T-nuts, internal and external hexagons, plastic wing nuts, blocks and other conventional products as well as some non-standard customized products, to help local farmers get rich.

Guangzhou Baiyun International Airport Section 1

Guangzhou Baiyun International Airport is located at the junction of Renhe Town, Baiyun District, Guangzhou City, Guangdong Province, Xinhua Street, Huadu District, and Huadong Town. It is about 28 kilometers away from the center of Guangzhou. It is a 4F-level civil international airport and one of the three major gateway complex hub airports in China. It is one of the top 50 major airports in the world. The airport was formerly the old Baiyun Airport built in the 21st year of the Republic of China (1932). In 1963, it was renamed Guangzhou Baiyun International Airport. On August 5, 2004, the new Guangzhou Baiyun International Airport was officially opened. On February 5, 2015, the third runway of Guangzhou Baiyun International Airport was put into use. On April 26, 2018, Terminal T2 of Guangzhou Baiyun International Airport was officially opened

On September 27, 2020, the third phase of the expansion project started. The main project includes two new runways, a 420,000 square meter T3 terminal and an apron with more than 190 parking spaces, with a planned total investment of more than 50 billion yuan. Our customers also participated in the expansion project and supplied the required products for one of the bidding sections. After the expansion project is completed, the T3 terminal will be a multi-modal transportation complex integrating aviation, highway, and railway (urban rail) at Baiyun Airport. The expansion project will simultaneously introduce the Guangzhou-Dongguan-Shenzhen intercity railway, Guangzhou-Hebei high-speed railway, Guangzhou-Zhongshan-Zhuhai-Macao high-speed railway, the second airport expressway and the northern extension of Metro Line 22. Guangzhou Baiyun International Airport is positioned as an international aviation hub that leads the construction of a world-class airport cluster in Guangdong, Hong Kong and Macao and supports the strategy of strengthening the civil aviation country. After the overall plan is completed, the annual maximum aircraft take-off and landing will be 870,000, the passenger throughput will be 140 million, and the cargo and mail throughput will be 6 million tons.

28th gold medal at the Tokyo Olympics: Women's track cycling team sprint

On August 2, 2021, Beijing time, the Tokyo Olympic Track Cycling Team Sprint was held. In the qualifying round, the Chinese team Zhong Tianshi and Bao Shanju won the second place. In the group stage, they faced the seventh-placed Lithuanian team. Zhong Tianshi and Bao Shanju entered the gold medal battle with a world record-breaking performance. In the final against the German team, Zhong Tianshi and Bao Shanju successfully won the gold medal. This is China's 28th gold medal in the Tokyo Olympics and Zhong Tianshi's second Olympic gold medal.

Subsequently, the China Cycling Association sent a letter of thanks to the supplier of bicycles ridden by Olympic athletes, in which the letter highly praised the Chinese track cyclists Zhong Tianshi and Bao Shanju for winning the championship and breaking the world record. They won honor for the motherland and the people, and greatly inspired and inspired the Chinese cycling community. The excellent results achieved by the Chinese cycling team are naturally inseparable from the long-term strong support and help of suppliers for the cycling project, and the company expressed its sincere gratitude to the suppliers. The letter also stated that the China Cycling Association hopes to continue to strengthen cooperation with them, work together to create the future, and jointly promote the better, faster, higher and stronger development of cycling, and make greater contributions to the construction of a sports power in my country. The bicycle supplier of the gold medal Olympic athlete is a long-term cooperative customer of our company. Our company has long supplied the fastener products required for the assembly of track bicycles for this customer, mainly stainless steel screws. This time, the Olympic athletes won the gold medal, and our company also sent blessings and thanks to the customer in time. I hope that in the future, we will work together to achieve a win-win situation.

Changzhou Dinosaur Park Hot Spring Project

Changzhou Dinosaur Valley Hot Spring is the first prehistoric theme hot spring resort in my country. It was listed as the top project of the "30 key tasks" and "Top Ten Greening Projects" of Changzhou Municipal Party Committee and Municipal Government in 2008 and the "50 key projects - Changzhou Leisure Exclusive Tourism Development Plan" in 2009. Dinosaur Valley Hot Spring covers an area of 280 acres, with 70 acres developed in the first phase and an investment of nearly 200 million yuan. It is a representative work of China's fifth generation of theme hot springs. As a member of the Global Dinosaur City, it has been rated as a 5A scenic spot and has been selected as a national hot spring executive director unit by the Hot Spring Tourism Branch of the China Tourism Association. It is the only one in Jiangsu. Changzhou Dinosaur Valley Hot Spring has five major hot spring pools, including Dongtian, Longchi, Health Leisure, Couple Romance and Nestle Forest. It consists of nearly 40 open-air pools such as red wine pool, essential oil pool, waterfall pool, whirlpool pool, fish pool, five elements Chinese medicine pool, etc. The largest theme dragon pool can accommodate 100 people at the same time. The garden is densely covered with flowers and trees, with fresh and fragrant dew and interconnected pavilions and corridors. It seems like a paradise, creating an urban forest and hot spring secret realm.

The project our company participated in the construction of was the Longtang Hot Spring, and we supplied the corresponding fastener products for the purification equipment and devices of this part. The purified hot spring water was tested by the Nanjing Mineral Resources Supervision and Inspection Center of the Ministry of Land and Resources, and its mineral content was extremely rich. What is particularly precious is that strontium and metasilicic acid exceed the international "Medical Hot Spring Standard" concentrated silica content and the national drinking natural mineral water standard. Strontium not only has the functions of improving cardiovascular, enhancing mental and muscle excitability, but also has an improvement and auxiliary effect on coronary heart disease and children's stature retardation. Metasilicic acid can cleanse the skin and has beauty effects such as softening keratin, anti-aging, and smoothing the skin. Because the quality, quantity, and temperature of the hot spring are rare in East China, it was awarded the honor of "Southern Jiangsu First Hot Spring Observation Center" by the Geothermal Center of the Jiangsu Provincial Department of Land and Resources. The Dinosaur Valley Hot Spring was collected from the Triassic stratum 2009.70 meters below the surface, about 250 million years ago, with a daily outflow of 500 cubic meters. The bottom temperature of the well is 82℃, and the outlet water temperature exceeds 55℃ all year round.